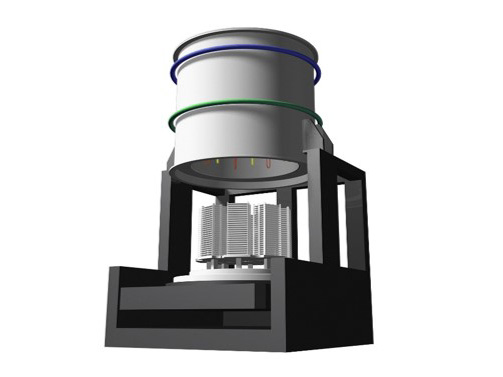

Cylindrical elevator batch kiln

| Maximum temperature | 1400℃ |

|---|---|

| Atmosphere | Air, Special atmosphere gas |

| Heat source | Electricity |

Effective demension

| Model | Size |

|---|---|

| A-AF-500 | 4piles φ500×400H(mm) |

| A-AF-850 | 8piles φ750×400H(mm) |

High Airtight Atmosphere Control

The multiplex seal structure provides superior air-tightness. This also allows for super low oxygen concentration with limited supply of gas.

Shorter Substitution Time in Kiln

NORITAKE original double gas supply method (direct supply + penetration supply) and vacuum decompression provides shorter substitution time, helping improve the overall production efficiency.

Uniform Temperature Distribution

Heaters are arranged around the circular setters to heat from all three directions.

Space saving and efficient production

Multiple kiln units and handing systems can be controlled automatically for space saving and efficient production.