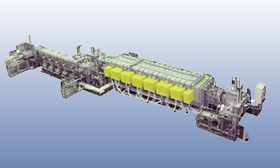

Continuous firing furnace which conveys works on base plates using and oil pressure system.

Mass production for homogeneous works and stable operation under high temperature are ensured.

| Maximum temperature | 1600°C |

|---|---|

| Atmosphere | Air, N2, N2 + H2, H2, O2, Ar, CO2 |

| Heat source | Electricity |

Stable Transportation

-

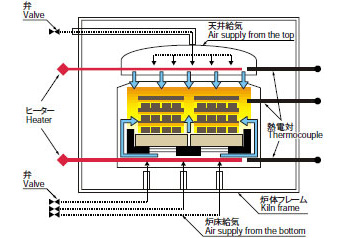

Our original design of the gas supply & exhaust holes allows for high precision atmosphere control possible. -

Air is supplied from both sides and center of the cross-section. Each valve can be individually adjusted, improving the atmosphere uniformity inside the kiln.

Layout example

Vacuum substitution system

N2consumption is reduced

Suitable to short cycle products. N2 consumption is reduced to Max.75%. (compared to our conventional model)

Insert Pusher

Stable Transportation

The practical pusher system for base plates has superior stability and reliability.

For precise control of transfer speed

Speed precision : Time difference ±1% (*Standard: ±2%)

High-temperature Continuous Firing

From de-binder temperature of 400°C to the firing temperature of over 1600°C , a wide range of heat treatment is available.

Lithium-ion battery materials, activated carbon, MLCC, thermistors, other electronic component materials, etc.